- Messages

- 20,210

- Location

- Springfield, Missouri

Well, my contractor pinged me on Friday and had the quote for my new shop ready.  We've decided to move forward with this as we still have two storage units up in KC and are paying a good chunk of coin for them each month, probably more than the items are worth in them for the most part, but that is an argument for another day and my shop is within grasp.

We've decided to move forward with this as we still have two storage units up in KC and are paying a good chunk of coin for them each month, probably more than the items are worth in them for the most part, but that is an argument for another day and my shop is within grasp.

I spent part of yesterday, laying out the location and shooting the grade to get an idea of how much fill we'll need. It's looking like we need 75 to 100 yards of fill due to the slope on the back side. Though the farm is 126 acres, we don't have a lot of good spots to build surprisingly due to the creek and flooding. I could start moving dirt from other places, but my tractor can only move about 3/4 yard per bucket, so I'd be looking at about 180 trips from a good distance where the fill soil isn't mostly sand. Time wise I think we're looking at using plant waste from the quarry, which goes for $35 per 20 tons (not including delivery).

The location puts it right off the driveway, about 25' between it and the garage to allow a well rig truck to get in to service the well, if need be.

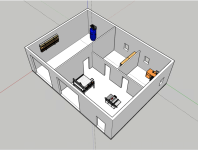

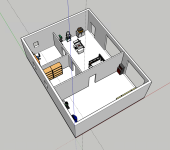

The contractor will be bringing by a color sheet for the metal this week. My wife is wanting a red/white/blue theme on the farm, so red would complete the look she was going for, with the house being white and the guest cabin blue. I was planning office space in the back corner, which is where most of the windows are, but may change them up before we get to the framing. I need to sit down and do some layout of tools and such, I want at least one or two windows in the shop area.

I spent part of yesterday, laying out the location and shooting the grade to get an idea of how much fill we'll need. It's looking like we need 75 to 100 yards of fill due to the slope on the back side. Though the farm is 126 acres, we don't have a lot of good spots to build surprisingly due to the creek and flooding. I could start moving dirt from other places, but my tractor can only move about 3/4 yard per bucket, so I'd be looking at about 180 trips from a good distance where the fill soil isn't mostly sand. Time wise I think we're looking at using plant waste from the quarry, which goes for $35 per 20 tons (not including delivery).

The location puts it right off the driveway, about 25' between it and the garage to allow a well rig truck to get in to service the well, if need be.

The contractor will be bringing by a color sheet for the metal this week. My wife is wanting a red/white/blue theme on the farm, so red would complete the look she was going for, with the house being white and the guest cabin blue. I was planning office space in the back corner, which is where most of the windows are, but may change them up before we get to the framing. I need to sit down and do some layout of tools and such, I want at least one or two windows in the shop area.