Hey, folks,

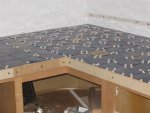

Got in 12 hours of work on the project yesterday: by midnight it was almost ready for tile! What's shocking is the hundred little things that needed to happen before the relatively simple step of putting down the 3/4 ply. The face frames got clamped, countersunk (using the drillbit from the pockethole jig) and screwed together using square drive face frame screws. Came out nice.

Had to build up the cabinet sides to accept screws without splittling (and to give me a large target area...

When I made the frigo cabinet, I saved a little green by using half inch MDF for the back. Big mistake! It got moved around a fair bit during all this, and of course I was too lazy to empty it before I moved it. Result? The sides pulled away from the back. Got some glue into the seams, and it took every clamp I had to get everything back in place:

Those cheap harbor freighters weren't much good for pulling things together, but they could hold what the besseys had tightened. so it was clamp, reclamp, reposition, clamp....

But it worked!

I counted my many blessings as I cut the plywood sheets with the festool. I got it because I was sick of wrestling 3/4" ply onto the table saw, and the way I was doing it was durned dangerous. One of the curses of a small shop! But I got the ply up on the rolling cabinet, got the chunks of 2" insulation under it, and went to town. Perfect. That thing is worth every penny in avoided doctor bills, and, based on the way I used to do it, is actually more accurate...

I had some stainless steel screws laying around from another project, so I used those to set down the ply.

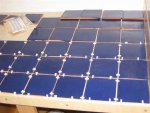

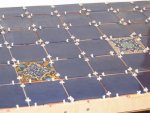

Next step: cut the sink hole, cement board, thinset and tile!

Thanks,

Bill