Jim O'Dell

Member

- Messages

- 2,783

- Location

- Between Aledo and Fort Worth, TX

We'll see. I can get the same stuff, Lowes and HD will order it. About 80.00 a sheet. Or I will try the distributor, and maybe at least save the 20.00 delivery fee. But it's a current style and finish, so I can wait (Here I go again ) for a while to go get it. Or go another direction altogether. I would like to have a real wood assembly table with vises and dog holes. Maybe this will be where that gets built, and let it double as the outfeed table. It is a straight shot from there to the future assembly/finishing room. The router table will live on the side of the saw that it can be used for the infeed table for sheet goods. I did that already cutting the MDF for the top, and it worked ok. Will be better when there is some weight on it so it doesn't slide on the feet so much. Right now it is so light that the Herc-U-Lift wants to keep the wheels engaged, even though it's in the down position.

) for a while to go get it. Or go another direction altogether. I would like to have a real wood assembly table with vises and dog holes. Maybe this will be where that gets built, and let it double as the outfeed table. It is a straight shot from there to the future assembly/finishing room. The router table will live on the side of the saw that it can be used for the infeed table for sheet goods. I did that already cutting the MDF for the top, and it worked ok. Will be better when there is some weight on it so it doesn't slide on the feet so much. Right now it is so light that the Herc-U-Lift wants to keep the wheels engaged, even though it's in the down position.

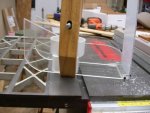

After cutting 2 of the apron stringers for half lap joints when they weren't supposed to be

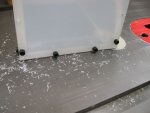

, I've recut new ones, got them set up, and started trimming the miscut ones for extra bracing on the inside just because most of the cuts are already made.

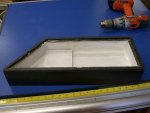

, I've recut new ones, got them set up, and started trimming the miscut ones for extra bracing on the inside just because most of the cuts are already made. I can already tell I probably won't get the laminate on today. Still need to cut the hangers to mount the top to the table and glue them to the bottom piece. a couple minor trims to make on one piece of bracing, then take it all down and glue and screw it back together. Then I can go back to the top.

I can already tell I probably won't get the laminate on today. Still need to cut the hangers to mount the top to the table and glue them to the bottom piece. a couple minor trims to make on one piece of bracing, then take it all down and glue and screw it back together. Then I can go back to the top.

Thanks for the encouragement! Jim.

After cutting 2 of the apron stringers for half lap joints when they weren't supposed to be

, I've recut new ones, got them set up, and started trimming the miscut ones for extra bracing on the inside just because most of the cuts are already made.

, I've recut new ones, got them set up, and started trimming the miscut ones for extra bracing on the inside just because most of the cuts are already made.Thanks for the encouragement! Jim.

Jim.

Jim.