- Messages

- 11,464

I just looked up the order and the steppers, motors and power supplies was all a bundle it came with the package from the suppliers 1 power supply one stepper for each motor.

Awesome. That's what I was hoping for!The spindle doen not need much flow. Mine is a small stream thru a small tube.

I have a flow meter with temperature.

I run hours continuos and maybe get to 85 degrees on the coolant.

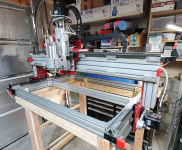

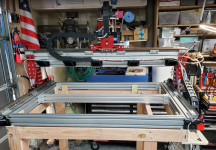

BRENT the start Button and the stop Button need to be in series, you show them in parallel. Then you need to use a Normally open set of contact from your control relay around the NO start button to seal it in. Then when you push the start button it will energize the control relay and the control relay aux contact will hold the relay energized until the stop push button interrupts the power and drops out the control relay. use a second set of contacts on the control relay to provide 110 volts to the main contactor.Well, been busy with a bunch of spring things over the last month or so and haven't moved all that fast on the CNC but have some time now to work on it.

I haven't done a whole lot with contactors or relays, and like to be cautious on this kind of stuff so have been trying to plan out exactly what the wiring diagrams should look like.

As a side note, I found a nice little 2d drawing app called draw.io that I used for these diagrams that is pretty easy to work with.

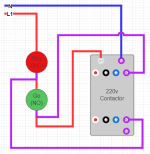

I'm going to have an E-stop on my machine that will connect to my controller that should stop it from sending signals to the motors and what not, but I'd also like to have something a little more physical that will cut power to all motors without necessarily slamming off power to the controller. Thats where the contactor will come into play. They say that in order to learn something, you need to be able to explain it, so here goes.

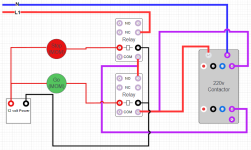

So a basic contactor 120v self holding circuit should look something like this. I'm using the normally open aux contact to keep the contactor energized. Pressing the Go button energizes the coil (A1->A2) engaging the contactor and closing the NO aux on the contactor, therfore keeping the coil energized and holding. Pressing the Stop button opens the circuit, de-energizing the coil and causing the contactor to disengage. In the case of a power outage, it will also cause the contactor to disengage, which would be nice if using to power on other motors.

This is the basic circuit using 120v to power the coil and 120volt momentary Normally closed (NC) and Normally open (NO) buttons.

View attachment 125803

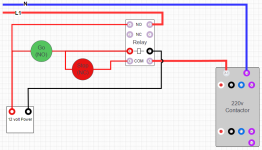

Now that's all fine and good, but I don't really want to run 120 volts out of my control enclosure to a control box. I'd rather use some 12 volt relays and simple momentary buttons to control the circuit.

This circuit is functionally the same as the previous one, with the exception of using some remote momentary buttons and 12 volt relays configured as NC and NO in order to operate the contactor.

View attachment 125804

I like the idea of a single relay. That does sound like a better solution.The stop button is a Normally closed button.. the botton is a normally open button. Both are momentary make/break button. the top relay will come on right away and drop out when you push the stop button and the bottom relay will stay off until you push the button and will drop out when you let go of the button, You don't need two relay only one is required if you will use the way I have described. This is how it was wired to begin with and it works.

two relay is two things to fail.

K.I.S.S. is my motto.

Thanks Darren. Now I need to wrap my head around this.I'm not good at draw.io, but this is my interpretation of how I'd do it using a DPDT relay and 12v to control the 120v for the contactor.

View attachment 125805

Look at the post right before your latest post. Its doneI showed you how to do it with one relay, call me if you don't understand. I have done this hundreds of time when I was a tech back in the day.

(Darn techies trying to make it to hard)....mumble mumble

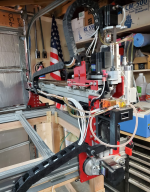

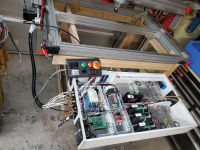

Looking good, I like that lighting. Is it rgb or just white?Well, decided I should plug it in and make sure the flappy paddle and circuit breaker works. No smoke yet, and the led's and fan powered up.

Need to hook up a few more wires and get the control panel running.

View attachment 125972