- Messages

- 11,669

- Location

- Constantine, MI

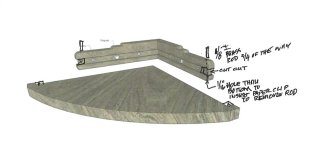

I'm designing some corner shelvs, about 12" deep, for a client. I want to hide the screws that attach it to the wall by setting them in a 1/4" deep groove behind the edge of the shelf and then set the shelf in to the groove. The shelf will be held in with a pair of rare earth magnets. To my eye it should work just fine. Am i missing anything?