- Messages

- 20,228

- Location

- Springfield, Missouri

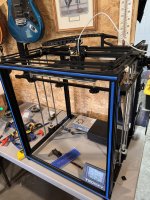

A while back I gave my grandson's dad my older 3d printer so they could work together on some projects. With my current printer going down this week, I thought it might be time to get a second printer again as a backup.

I ordered this one, which has auto bed leveling and a filament sensor.

Besides being a larger bed/capacity, it is the cube type, which will allow me to enclose it for temperature control. Overall it had decent reviews, just needs the normal upgrades of better belts, and mosfet relays for added safety.

I'll document the changes I do and review it here.

I ordered this one, which has auto bed leveling and a filament sensor.

TRONXY Large Pulley 3D Printer X5SA DIY Auto Level Filament 330*330*400mm 24V US | eBay

All X5SA 3D Printer have been upgrade. Model: X5SA. Host Computer Software: TRONXY slice, Cura, Repitier-Host, Simplify 3D. X5SA is a 3D printer specially developed for people who like large-size printing and DIY.

www.ebay.com

Besides being a larger bed/capacity, it is the cube type, which will allow me to enclose it for temperature control. Overall it had decent reviews, just needs the normal upgrades of better belts, and mosfet relays for added safety.

I'll document the changes I do and review it here.