- Messages

- 11,669

- Location

- Constantine, MI

These days you can search Google and Facebook and find owners groups for everything from Bugatti's to bug repellent. So, why can't I find an owners group for Rikon tools? I was able to turn up one very small private group for one of their lathes, but nothing else.

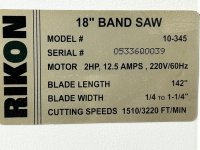

The fence on my 'original green' 18" band saw has always been the week link on this machine and I have toyed with getting a replacement. The company, as far as I can tell, does not offer an upgrade so aftermarket may be the way to go. Thinking I might gain some insight from other users I went looking for a forum or group - none to be found.

The fence on my 'original green' 18" band saw has always been the week link on this machine and I have toyed with getting a replacement. The company, as far as I can tell, does not offer an upgrade so aftermarket may be the way to go. Thinking I might gain some insight from other users I went looking for a forum or group - none to be found.