- Messages

- 16,600

- Location

- Reno NV

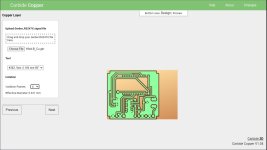

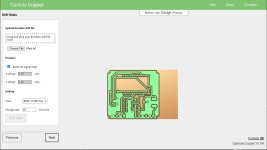

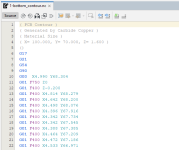

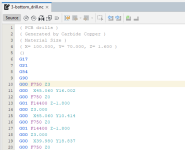

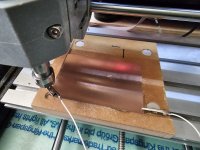

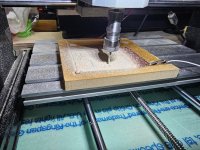

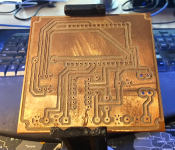

A while back I had bought a little desktop 3018 cnc machine with the thoughts I could use it to make circuit boards. Not really PCB's, but MCB's (Milled Circuit Boards).

Been playing with it for a while and it's been a bit of a learning curve to get through, but I've finally got it down I think.

I was wanting to update the shelves I use for my Record collection. I had put some addressable led strips on them before, but did not like the way I had the leds strips mounted. I had them on some brackets that held them out in front. I ordered some new shelves (as I needed more room). They are the standard ikea type crap, but they should work to hold records till I get tired of them and someday make something else to hold them. At any rate, I 'modified' the shelves to add a dado in them to hold the light strips. Thats the only part of this project that is remotely woodworking related.

There is a library out there called "WLED" that works with addressable led strips/strings that runs on ESP32 microcontroller boards that has built in web server for control and a whole lot of other functions and presets for interesting animations. Theres also a fork of it that can use a microphone that will let it do sound reactive animations, and that's what I wanted to use. I already has some of the microcontrollers laying around, and didn't want to buy a prefabbed board, and really didn't find any that had the microphones built in, so I decided to bite the bullet and design my own board.

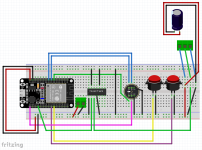

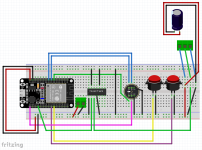

I used to use Fritzing for doing some basic board design, as it has a nice little breadboard type interface that lets you design a schematic and board based on a breadboard type design. It was nice, but was limited in options for doing footprints for components and was kind of a pain in certain ways.

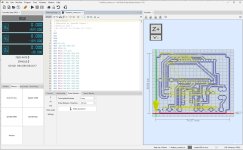

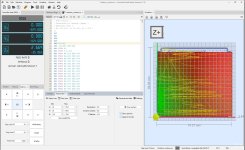

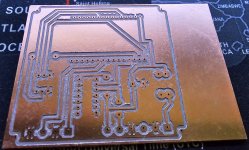

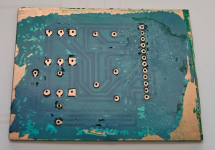

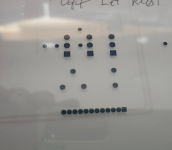

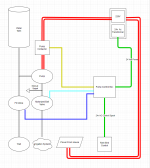

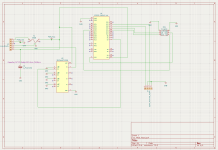

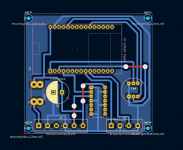

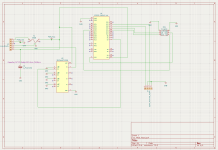

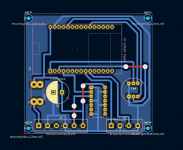

So I decided I'd move up to using something called KICAD. With KICAD, you draw up the schematic first, and then use a pcb design tool to layout the components and traces. I was surprised it wasn't all that hard to learn and was much easier to adjust footprints and trace widths.

This tutorial gave me all I needed to work through it. Kicad Tutorial

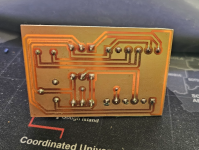

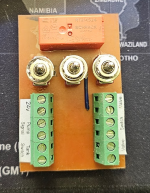

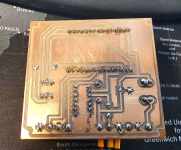

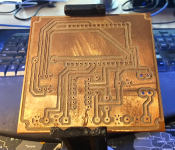

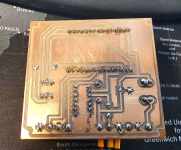

This is what I ended up. Not the greatest soldering job in the world , but the board works just fine.

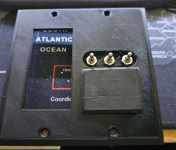

And this is the end result. Now I need to get the records out of the stack of boxes in the bedroom and onto the shelves!

Been playing with it for a while and it's been a bit of a learning curve to get through, but I've finally got it down I think.

I was wanting to update the shelves I use for my Record collection. I had put some addressable led strips on them before, but did not like the way I had the leds strips mounted. I had them on some brackets that held them out in front. I ordered some new shelves (as I needed more room). They are the standard ikea type crap, but they should work to hold records till I get tired of them and someday make something else to hold them. At any rate, I 'modified' the shelves to add a dado in them to hold the light strips. Thats the only part of this project that is remotely woodworking related.

There is a library out there called "WLED" that works with addressable led strips/strings that runs on ESP32 microcontroller boards that has built in web server for control and a whole lot of other functions and presets for interesting animations. Theres also a fork of it that can use a microphone that will let it do sound reactive animations, and that's what I wanted to use. I already has some of the microcontrollers laying around, and didn't want to buy a prefabbed board, and really didn't find any that had the microphones built in, so I decided to bite the bullet and design my own board.

I used to use Fritzing for doing some basic board design, as it has a nice little breadboard type interface that lets you design a schematic and board based on a breadboard type design. It was nice, but was limited in options for doing footprints for components and was kind of a pain in certain ways.

So I decided I'd move up to using something called KICAD. With KICAD, you draw up the schematic first, and then use a pcb design tool to layout the components and traces. I was surprised it wasn't all that hard to learn and was much easier to adjust footprints and trace widths.

This tutorial gave me all I needed to work through it. Kicad Tutorial

This is what I ended up. Not the greatest soldering job in the world , but the board works just fine.

And this is the end result. Now I need to get the records out of the stack of boxes in the bedroom and onto the shelves!

Last edited: