glenn bradley

Member

- Messages

- 11,571

- Location

- SoCal

I am killing a bit of time while building the dressers for the new bedroom suite. The son of a family friend wants a media cabinet to hold his cable box, gaming console and so forth. The location is his bedroom so the scale is small. He called me and asked about making one out of 2x4's so I offered to intervene and do something not quite as rough out of some materials I had on hand. We have agreed on something like so.

The top will be sealed pine. The base will be painted white to match an existing desk unit.

The pine I had on hand from a project that never sow the light of day so . . . bonus for him ;-).

I milled and glued up some pine to make a top that echos the commercial desk unit he already has. I use some epoxy to lock and level some knots.

No dye in this epoxy as the top coat will be an amber coloration.

Not sure what I was trying to show here. We have all (or mostly all glued up panels before.

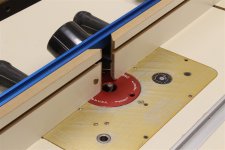

Ripping some poplar which will be the base material (mostly) under primer and paint.

The top will be sealed pine. The base will be painted white to match an existing desk unit.

The pine I had on hand from a project that never sow the light of day so . . . bonus for him ;-).

I milled and glued up some pine to make a top that echos the commercial desk unit he already has. I use some epoxy to lock and level some knots.

No dye in this epoxy as the top coat will be an amber coloration.

Not sure what I was trying to show here. We have all (or mostly all glued up panels before.

Ripping some poplar which will be the base material (mostly) under primer and paint.

Last edited: