Stuart Ablett

Member

- Messages

- 15,917

- Location

- Tokyo Japan

I had a blast in Osaka, I was worked like a rented mule and loved it

Everyone was great, the food was great, and free! We worked from about 8:30 AM until at least 9:30 PM all three days, and I tell you it was some job, nerve wracking, stupid busy, hurry up and wait and so very very rewarding.

The chairs got shipped to Osaka on the 18th, the same day we left at night for Osaka, I was put up in a nice room at the ANA Crowne Plaza hotel, a quick 10 min walk to the site.

The workshop area, called "54" because on regular tour that is the number of the semi trailer that the shop lives in, was sparse but well stocked with most stuff I could need. It is in a tent, but no AC, and it was hot and humid the whole time I was there, by noon each day my shirt was soaking wet, but I did not care a lick, I was enjoying myself too darn much!

That is 54, the silver cases hold the new chairs that I was working on, in fact during the time I was down there, until I handed the chairs off to the coach and artists, they were "My Chairs" and I was VERY protective of them.

Of course the first day things started with a visit from Mr. Murphy, of the six items shipped from Tokyo, only 5 arrived, that was three cases of chairs and my two tool boxes, the fourth case of chairs was late, and of course, it held the #1 and #2 chairs

Oh well there were other things to work on. The white stand, or tower, as it is called in the second pic inside the 54 is the new all aluminum unit that is supposed to go with the new chairs, but it had way too much flex on the plate on top, that needed to be fixed, so I got out the angle grinder and some cutting wheels and removed the welds that held the plate in place. I'll be building a new wooden top for the tower, that will NOT flex like the aluminum plate did. That should be arriving tomorrow..... with my two tool boxes.

Back to the new chairs.

One of the artists, Gongli, came in early to look at the chairs, he was very happy with what he saw, in fact he said he thought they looked perfect, very high praise indeed. He was eager to get the chairs out so they could try them. We could only try four at a time because we could not use the stage area, or the artist training tent where the safety lines are located, but we did four at time and they were very happy. Still some shims were needed, and we made copious notes and then I did some very minor but needed adjustments, as well as some changes that were not in the original plan. It seems that once they figured out they had a real wood worker with some sharp tools on site, they wanted to go the extra step of having me adjust the fit of the chairs in relation to each other.

Finally on Sunday night, after three solid days of work, fiddling and fitting we got to try all eight chairs.......

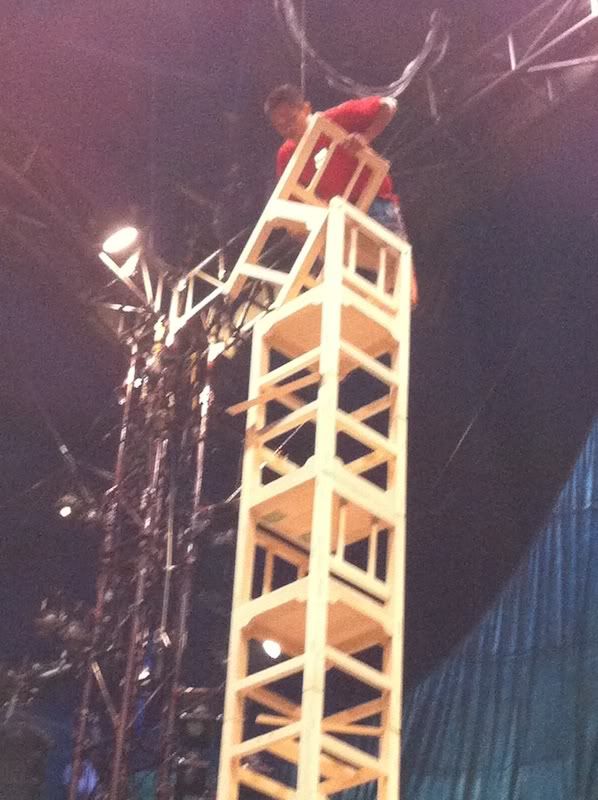

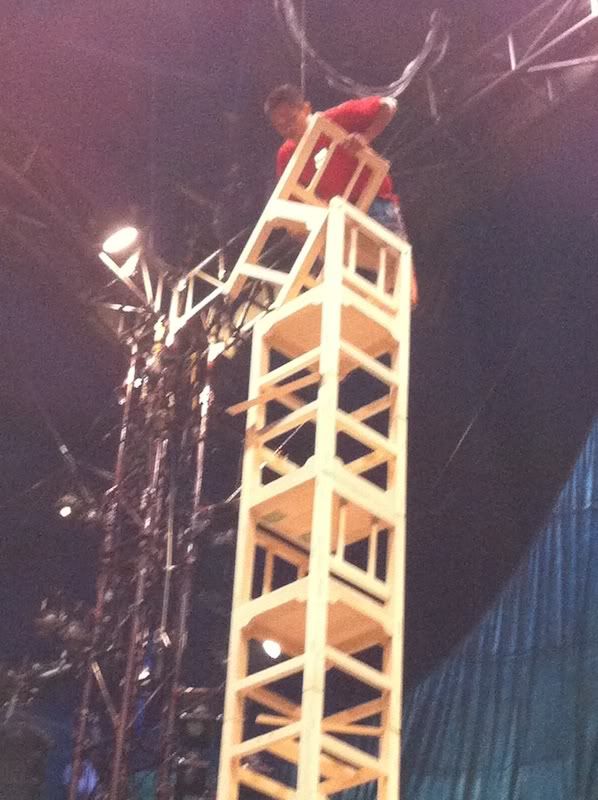

That is Bo, the other artist on top, with Gongli looking up the stack of chairs.

The coach walking by, this fellow is in his 60's and is in amazing shape, even though he spoke no English, and I no Chinese, we still communicated well, I would understand what he was talking about before the artists did.

I used my resaw bandsaw to slice up some wood to make shims, I went from 0.5mm to 1.5mm in .05mm steps, he was very pleased to get these as they have to constantly shim the chairs due to changes in the weather etc.

Here Bo is doing the last move of the trick, the chair is reversed and it actually hooks into two hooks on the back of the #7 chair, and the legs go down into notches on the #7 chair, then with the chair in that position, they do an amazing handstand.

Doing this work was hard, but very, very rewarding, and I think I might get the contract for a new set of chairs, fingers crossed!

So much more to tell, but that will have to do for now!

Everyone at Cirque was just great, very professional, but at the same time, very friendly and they know their jobs.

Cheers!

Everyone was great, the food was great, and free! We worked from about 8:30 AM until at least 9:30 PM all three days, and I tell you it was some job, nerve wracking, stupid busy, hurry up and wait and so very very rewarding.

The chairs got shipped to Osaka on the 18th, the same day we left at night for Osaka, I was put up in a nice room at the ANA Crowne Plaza hotel, a quick 10 min walk to the site.

The workshop area, called "54" because on regular tour that is the number of the semi trailer that the shop lives in, was sparse but well stocked with most stuff I could need. It is in a tent, but no AC, and it was hot and humid the whole time I was there, by noon each day my shirt was soaking wet, but I did not care a lick, I was enjoying myself too darn much!

That is 54, the silver cases hold the new chairs that I was working on, in fact during the time I was down there, until I handed the chairs off to the coach and artists, they were "My Chairs" and I was VERY protective of them.

Of course the first day things started with a visit from Mr. Murphy, of the six items shipped from Tokyo, only 5 arrived, that was three cases of chairs and my two tool boxes, the fourth case of chairs was late, and of course, it held the #1 and #2 chairs

Oh well there were other things to work on. The white stand, or tower, as it is called in the second pic inside the 54 is the new all aluminum unit that is supposed to go with the new chairs, but it had way too much flex on the plate on top, that needed to be fixed, so I got out the angle grinder and some cutting wheels and removed the welds that held the plate in place. I'll be building a new wooden top for the tower, that will NOT flex like the aluminum plate did. That should be arriving tomorrow..... with my two tool boxes.

Back to the new chairs.

One of the artists, Gongli, came in early to look at the chairs, he was very happy with what he saw, in fact he said he thought they looked perfect, very high praise indeed. He was eager to get the chairs out so they could try them. We could only try four at a time because we could not use the stage area, or the artist training tent where the safety lines are located, but we did four at time and they were very happy. Still some shims were needed, and we made copious notes and then I did some very minor but needed adjustments, as well as some changes that were not in the original plan. It seems that once they figured out they had a real wood worker with some sharp tools on site, they wanted to go the extra step of having me adjust the fit of the chairs in relation to each other.

Finally on Sunday night, after three solid days of work, fiddling and fitting we got to try all eight chairs.......

That is Bo, the other artist on top, with Gongli looking up the stack of chairs.

The coach walking by, this fellow is in his 60's and is in amazing shape, even though he spoke no English, and I no Chinese, we still communicated well, I would understand what he was talking about before the artists did.

I used my resaw bandsaw to slice up some wood to make shims, I went from 0.5mm to 1.5mm in .05mm steps, he was very pleased to get these as they have to constantly shim the chairs due to changes in the weather etc.

Here Bo is doing the last move of the trick, the chair is reversed and it actually hooks into two hooks on the back of the #7 chair, and the legs go down into notches on the #7 chair, then with the chair in that position, they do an amazing handstand.

Doing this work was hard, but very, very rewarding, and I think I might get the contract for a new set of chairs, fingers crossed!

So much more to tell, but that will have to do for now!

Everyone at Cirque was just great, very professional, but at the same time, very friendly and they know their jobs.

Cheers!