- Messages

- 16,602

- Location

- Reno NV

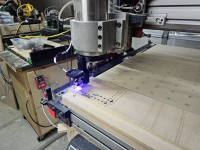

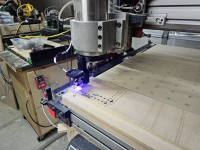

Jealous of all the laser work I've seen here lately, so decided to add one to the CDB CNC.

I had an old jtech photonics 2.8w laser laying around. I decided instead of rushing out to buy a new one, I should get this one working as a test bed and see if I need an upgrade later.

So drew up a quick detachable laser mount, ran some cables, added some quick connects and one reversing of a connection later, I've got it running!

Now to figure out how to focus it and use it again. lol.

I had an old jtech photonics 2.8w laser laying around. I decided instead of rushing out to buy a new one, I should get this one working as a test bed and see if I need an upgrade later.

So drew up a quick detachable laser mount, ran some cables, added some quick connects and one reversing of a connection later, I've got it running!

Now to figure out how to focus it and use it again. lol.