- Messages

- 16,602

- Location

- Reno NV

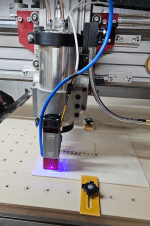

Got some 8mm Air tubing in today, so ran it through the cable chains. So glad the cable chains are big and beefy. Got a lot of stuff running through them, but they are getting kind of full now.

I had bought a 12 volt air solenoid valve a while ago, so hooked it up to the tubing, and put a quick connect for my shop compressor on the other end.

I've got a 120 volt outlet seperated into 2 different circuits, each hooked up to a relay in the control box controlled by a rocker switch on the control panel at this point. So I just plugged a transformer into one side and hooked that up to the valve. Works perfect.

On the other end, I had bought a goose neck mister attachment. It has a quick connect for the 8mm tubing, and a 4mm quick connect for adding lubricant. I got this for if I wanted to do Aluminum on the machine. They say you can do a little mist of isopropyl alcohol and that it provides lubrication and cooling without making too much of a mess. The air blowing the chips out is supposed to help a lot too.

My new laser should get here tomorrow, so I'll figure out a way to switch the air between this device and the air assist for the laser.

Really like that I can just flip a switch and have the air turn on and off easy from the control panel.

I had bought a 12 volt air solenoid valve a while ago, so hooked it up to the tubing, and put a quick connect for my shop compressor on the other end.

I've got a 120 volt outlet seperated into 2 different circuits, each hooked up to a relay in the control box controlled by a rocker switch on the control panel at this point. So I just plugged a transformer into one side and hooked that up to the valve. Works perfect.

On the other end, I had bought a goose neck mister attachment. It has a quick connect for the 8mm tubing, and a 4mm quick connect for adding lubricant. I got this for if I wanted to do Aluminum on the machine. They say you can do a little mist of isopropyl alcohol and that it provides lubrication and cooling without making too much of a mess. The air blowing the chips out is supposed to help a lot too.

My new laser should get here tomorrow, so I'll figure out a way to switch the air between this device and the air assist for the laser.

Really like that I can just flip a switch and have the air turn on and off easy from the control panel.

Last edited: